Thermal shock refers to the exposure of a surface to sudden and significant changes in temperature. In a food & beverage flooring application, this is often used in the context of hot water or pressure steam cleaning a surface for disinfectant purposes. This persistent thermal cycling from hot to cold temperatures can cause cracking, peeling and delamination of the flooring system.

Thermal shock refers to the exposure of a surface to sudden and significant changes in temperature. In a food & beverage flooring application, this is often used in the context of hot water or pressure steam cleaning a surface for disinfectant purposes. This persistent thermal cycling from hot to cold temperatures can cause cracking, peeling and delamination of the flooring system.

Hot Water & Steam Cleaning

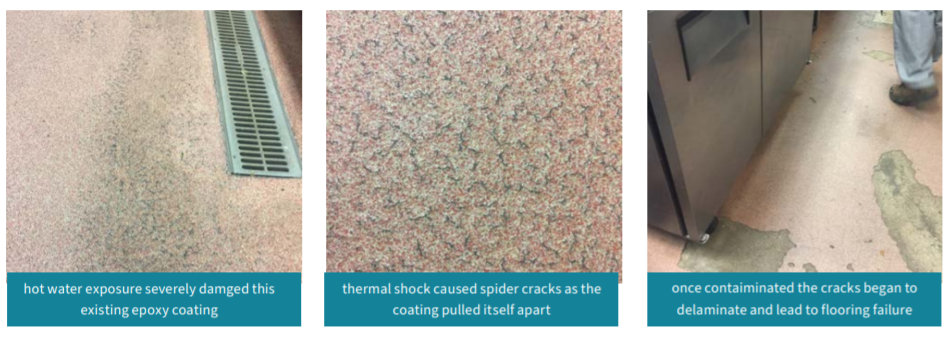

While quite effective, hot water or steam cleaning exposes flooring surfaces to significant thermal shock. This is often a regular occurrence as part of daily maintenance procedures. Excessive and consistent thermal shock will cause the substrate and protective flooring system to expand and contract at different rates, effectively pulling itself apart. Flooring systems in these settings should effectively dissipate the heat and if needed, expand and contract at similar rates to the concrete substrate.

Not All Floor Coatings Are Created Equal

In addition, epoxy floor coatings, if not properly designed will also easily fail. In these cases, thermal shock will cause the floor coating and underlying substrate, usually concrete, to expand and contract at different rates. This persistent kinetic motion eventually causes the coating to pull itself apart from the concrete leading to spider cracks, contamination and eventual failure. This same type of a scenario is common with epoxy and other heavy-duty grouts within quarry tile applications.

To get a more comprehensive understanding of food and beverage flooring download Resinwerks' free guide. We cover design considerations, curtailing bacteria growth, thermal shock implications, maintenance and long-term durability, and about polyurethane concrete in it. Download this valuable resource today.

Previous article

Previous article