Proper Mixing & Application Tooling

Proper application at the intended thickness will help to ensure a desired finish and limit waste Appropriate mixing and application tooling is a critical component to any successful installation. Today there are many types of brooms, squeegees and other materials to select from. Selecting the proper tooling will depend primarily on the intended application thickness as well as the overall viscosity of the material.

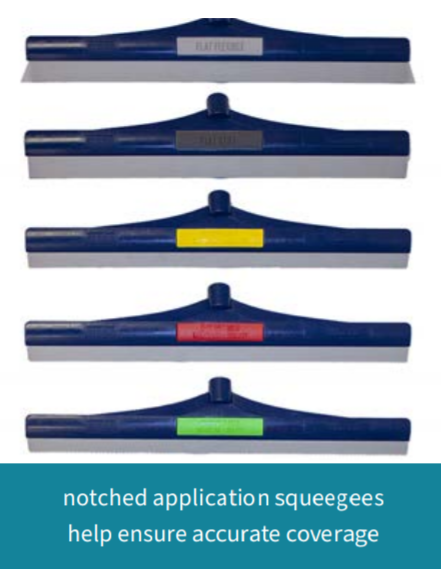

Experienced coating installers take great care to limit waste on projects. A wasted gallon or even a quart of material per job over the course of an entire season can add up to significant unnecessary expense. notched application squeegees help ensure accurate coverage

Squeegees

Speed Squeegees

- Available in both 18” and 24” widths

- Color coded and easy to understand varying application thicknesses

- Easy to clean and change out

Standard Notched Squeegees

Notched squeegees are available in varying sizes depending on the intended thickness. Usually these sizes range from 1/16” on up. They are also available in varying levels of stiffness.

Notched squeegees are available in varying sizes depending on the intended thickness. Usually these sizes range from 1/16” on up. They are also available in varying levels of stiffness.

Flat Squeegees

- Flat squeegees are ideal for wiping coatings tight – typical of thin epoxy primers or similar applications. Some installers will also use flat squeegees or magic trowels to apply coatings for certain decorative applications as well as topcoats.

Rollers

For residential garage floors, rollers are primarily used for back-rolling and finishing. The thinner the nap the thinner the application thickness. So in general, a 3/16” nap will apply thinner than a 1/4” nap. Rollers are well suited for thinner materials that are intended to be dipped and rolled out of a roller pan. They do not work well for spreading higher solids or thicker materials over a floor.

Mixing Buckets

Graduated buckets with clearly marked volume markings help installers accurately mix materials as per spec. Buckets should be kept clean from project to project and even mix to mix to minimize the potential of product cross contamination.

Proper volumetric mix ratios should be clearly marked on the buckets to help eliminate the potential for any off-ratio mixing. For clear buckets this can be achieved with a simple permanent black marker. When mixing pigmented materials, the mixing line levels often become covered with material. This can be remedied by inserting a screw through the side of the bucket to mark appropriate mixing levels so that the fill line is clearly visible inside of the bucket. Always mix only the amount that can be applied within the manufacturer’s recommended working time.

Coverage Rates

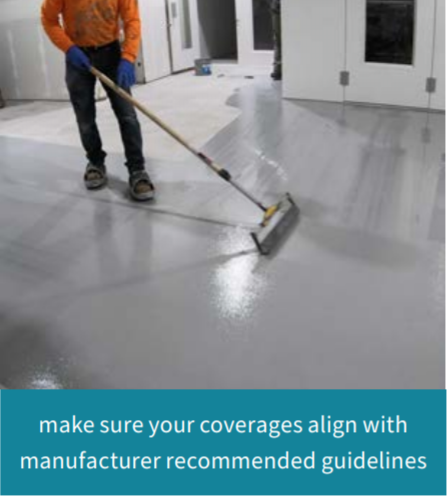

For every installer, hitting your manufacturer recommended coverage rates is critical to ensuring proper performance of your floor and keeping your material usage (and expenses) in line. Often overlooked in garage floor applications, proper material coverage is a key component to the profitability of your project.

Follow Your Manufacturer Recommended Thickness

For the most part, garage flooring installers are installing chip/flake broadcast floors as well as decorative metallic and basic solid color floors. Your material manufacturer should provide clear recommendations for the appropriate coverage rate of each material at each step in the process for the system you are installing.

For the most part, garage flooring installers are installing chip/flake broadcast floors as well as decorative metallic and basic solid color floors. Your material manufacturer should provide clear recommendations for the appropriate coverage rate of each material at each step in the process for the system you are installing.

- For example, if you are installing a lower-solids water-based epoxy primer, that will likely go down thinner than a high solids primer which has a higher (thicker) viscosity.

- Some materials, such as vapor barrier epoxies are designed to function in a certain way and have very clear guidelines on the appropriate manufacturer recommended thickness.

- Other products, such as polyaspartics may be used as both a broadcast coat and a grout/topcoat. In these situations, the coverage rate of your base coat will often differ from the coverage rate for your topcoat. Its important to understand the difference for each product in each step of your system’s application.

Application Tooling

- As mentioned prior, the tools with which you apply materials will obviously have a significant impact on hitting the intended coverage rates. Using the appropriate application squeegee will determine if or not you apply a material at the intended thickness and therefor the appropriate coverage.

- Keep your scrapers fresh: Chip & Flake broadcast floors perform well and are extremely popular for garage floor coatings. A proper scrape of broadcast chip is key to an even finish as well as achieving the manufacturer recommended coverage rates. Old and dull scrapers do not scrape consistent and will end up costing you $$$.

- At the end of each coat, track your coverage. Confirm your usage for the footage you calculated and see how it lines up with your intended coverage rate. If your coverages were off, determine why and remedy for future jobs.

Proper Material Staging

One of the most overlooked strategies for new coating contractors is proper staging prior to an application. Make sure your Part As and Part Bs are clearly separated and marked accordingly (also be sure to mark the lids with a sharpie).

One of the most overlooked strategies for new coating contractors is proper staging prior to an application. Make sure your Part As and Part Bs are clearly separated and marked accordingly (also be sure to mark the lids with a sharpie).- Once you have determined your appropriate coverage rate, stage your mixes for your project. It is best practice to organize and pre-measure all mixes so your application runs as smooth as possible. Leaving an additional extra mix available is a good idea should you require it.

Looking for more quick tips like these? Learn how to:

- Manage climate concerns

- Minimize waste and expense

- Optimize your work environment

In this guide for residential flooring installers. Click the button below to download.