Over the last several years, Resinwerks has helped both new and experienced garage flooring installers improve their installations. During that time we have seen all types of mistakes - some more common than others and ALL avoidable.

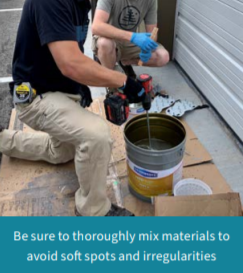

1. Not Mixing Properly

Ratios: Different types of floor coating materials will have different mix ratios. Staying on target with manufacturer recommended mix ratios is critical to avoiding costly mistakes. Material that is mixed off ratio will likely not cure through as it was intended or worse - not cure at all. Use clearly marked graduated mixing buckets to avoid these costly mistakes.

Ratios: Different types of floor coating materials will have different mix ratios. Staying on target with manufacturer recommended mix ratios is critical to avoiding costly mistakes. Material that is mixed off ratio will likely not cure through as it was intended or worse - not cure at all. Use clearly marked graduated mixing buckets to avoid these costly mistakes.

Mix Resins First: A common issue with new coating contractors is that they fail to mix up their part A or resins before catalyzing with their activators (part B). Not mixing your part A could lead to an uneven resin dispersion, causing some areas of your floor to remain tacky. This is especially important for pigmented coatings. Pigments not properly dispersed prior to application may create soft spots in the floor that will never dry at all.

Mix Correctly: Not mixing for enough time or over-mixing can also lead to issues. Carefully

follow your manufacturer recommended guidelines for mixing.

2. Applying Materials too Thin or too Thick

- One of the most frequent issues for new installers doing vinyl chip broadcast systems is that they try and stretch the broadcast coat to save money on materials. This leads to a very thin and often inconsistent base for which broadcast flake to settle. The result is a patchy floor that will require expensive repairs.

- Materials applied too thick may take longer to cure, bubble or even mud-crack. Use proper

tooling and follow manufacturer recommended coverage rates.

3. Poor Surface Preparation

- The leading cause of failure in garage floor coatings is poor surface preparation. Proper surface preparation is a multi-faceted component to the long-term success of any project. Floors must be mechanically profiled to remove the cream or top layer of concrete.

- Any loose dust or debris not properly vacuumed prior to coating application will constitute

a bond-breaker. Contaminated floors saturated with oil, grease and silicone must also be

properly treated with an effective de-greasing or emulsification agent.

These are just three of our top 10 rookie coater mistakes. If you thought, ouch I've done, while reading this blog post you need to know the remaining seven. If not, see if you can stump us for the last of them. I bet not. We've all been there! Download the 10 Rookie Mistakes Beginning Coaters Make by clicking below.

Previous article

Previous article