Thermal Shock & Oleic Acid Resistant

The BioCem™ polyurethane concrete systems from Resinwerks™ are engineered for fast turnaround with performance suited for the most demanding applications, including slabs with elevated moisture vapor emissions. Due to its high tolerance for thermal shock, BioCem is a preferred choice for applications such as brewery floors, restaurant kitchens, and food manufacturing.

These green-friendly systems are completely VOC-Free and incorporate a range of carbon-neutral bio-based raw materials. BioCem forms a seamless impermeable surface that is completely resistant to harsh chemicals as well as oleic acid byproducts generated by enzymatic cleaners.

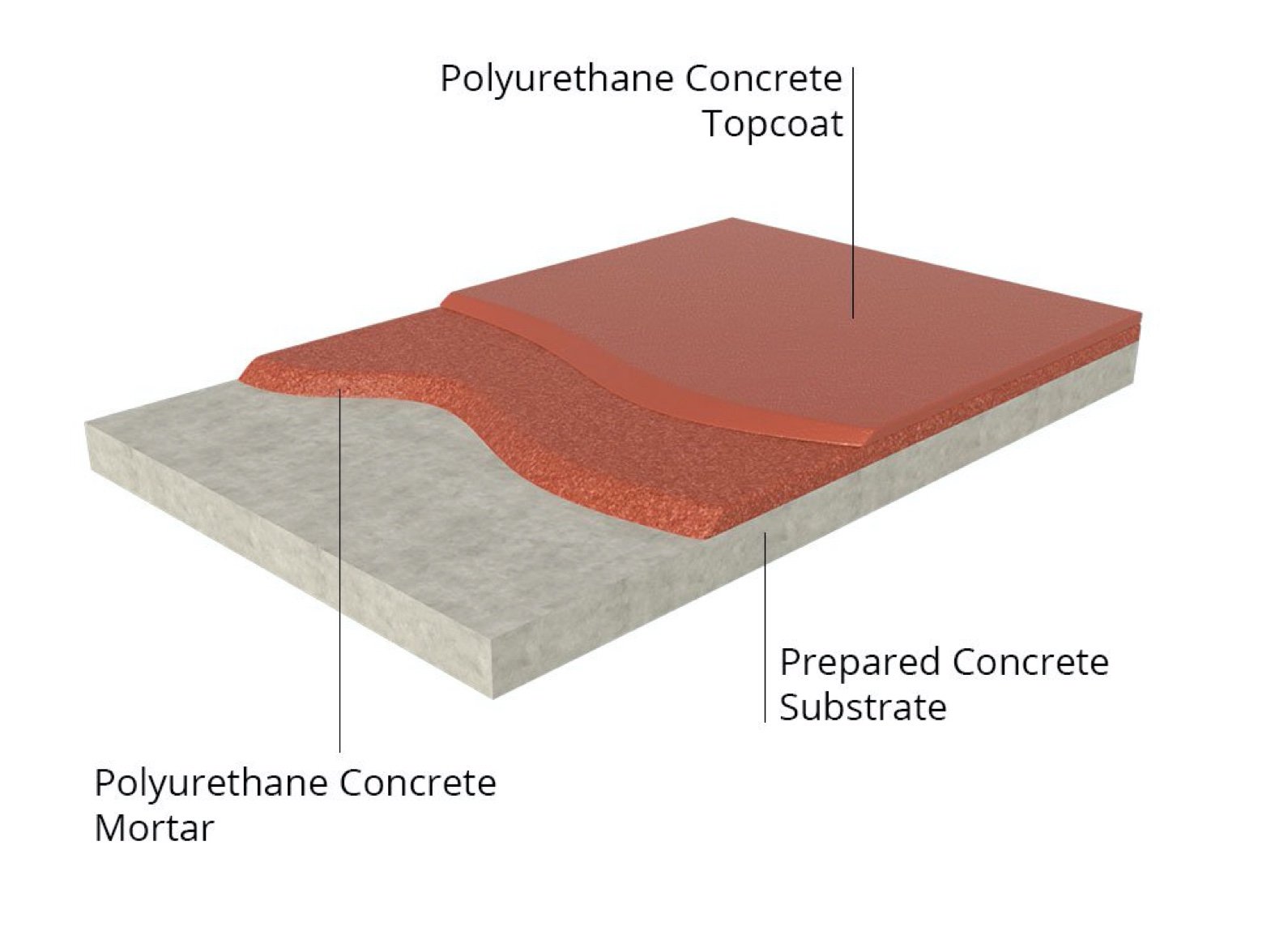

Polyurethane Concrete Systems

BioCem polyurethane concrete systems can be constructed in a number of ways to suit the needs of the application. Applied anywhere from 1/8" to 1", Resinwerks' BioCem SL and BioCem MF applications may also incorporate an integral perimeter cove base that can be troweled up vertical surfaces, leaving a completely seamless horizontal to vertical transition.

These coatings can be top-coated with the BioCem TC topcoat system or any of our other high-performance urethane or polyaspartic topcoats. Texture may also be adjusted from completely smooth to very rough depending on the requirements of the project. In addition, Bio-Cem™ polyurethane concrete may be used as a base coat for any number of Resinwerks systems including decorative chip, quartz, and solid color applications.

Bio-Cem SLB

A self-leveling polyurethane cement application, a basecoat of BioCem SL at 1/8” is broadcast to rejection with specialized quartz aggregate to a thickness of 3/16”. This system is then topcoated with high-performance BioCem TC topcoat. SLB provides a lightly textured surface ideal for light to medium duty food & beverage applications.

Bio-Cem SL-Smooth

A self-leveling polyurethane cement application with a smooth non-textured finish, this system utilizes a basecoat of BioCem TC as a primer followed by Bio-Cem SL at 1/8”. SL-Smooth provides an easy to clean, smooth finish ideal for food & beverage applications undergoing frequent wash downs.

BioCem MF

A heavy-duty urethane cement system utilizing BioCem Monofloor applied at 3/16”, MF slurry is then broadcast with specialized quartz aggregate to a 1/4” thickness and topcoated with BioCem TC polyurethane cement. MF is ideal for areas experiencing heavy thermal shock such as brewery production areas and commercial kitchens.

BioCem SF

An ultra-heavy-duty polyurethane concrete application incorporating larger aggregates for enhanced thermal shock resistance. BioCem SF slurry is applied at a thickness of 3/16"-1/4" and broadcasted with specialized quartz aggregate. This system can be top-coated with either a polyurethane concrete or a pigmented high-solids polyaspartic depending on desired finish. SF is excellent for environments experiencing significant levels of thermal shock, impact, and chemical attack.

Bio-CEM HF

Trowel applied polyurethane concrete designed for heavy duty applications. HF is installed at a thickness of 1/4” to 1/2”. This ultra heavy duty polyurethane concrete is designed for the most demanding environments experiencing significant levels of thermal shock, impact and chemical attack. It is designed as a single coat; self-sealing application and is best suited for environments requiring a high-degree of protection.

Bio-Cem SLF

A hybrid Urethane Cement / Decorative Flake broadcast system engineered for applications requiring a self-leveling base coat. This system incorporates a 1/8” polyurethane concrete slurry primer, followed by a decorative flake broadcast. The SLF system is grouted with a water-clear and chemical resistant 100% solids epoxy and finished with an aggregate fortified high-wear urethane in either a semigloss or satin finish.

Bio-Cem SLQ

Industrial strength decorative quartz flooring application for ultra-heavy-duty applications. This system incorporates a 1/8” polyurethane concrete slurry primer, followed by a double broadcast quartz. The SLQ system is grouted with a water-clear and chemical resistant 100% solids epoxy and finished with an aggregate fortified high-wear urethane in either a semigloss or satin finish. Available in an unlimited number of colors and blends, this system can be modified to accommodate varying substrate conditions, installation time-frames, and coefficient of friction (traction) requirements.

CASE STUDY

Rodizio Grill

As one of the very first Brazilian Steak House chains in North America, this restaurant has been serving large quantities of fine meats and other products for decades. These restaurants are extremely high-traffic applications, with chefs and servers working feverishly to deliver all you can eat steaks, chicken and anything else you can imagine. As such, a sanitary flooring system is critical for safety and efficiency. See how Resinwerks solved their flooring challenges on a tight timeline by clicking the link below.

LEARN MOREFlooring System Guide

Learn more about how Resinwerks BioCem polyurethane concrete can help your facility stay clean and safe with flooring that offers exceptional resistance to aggressive chemicals as well as mechanical and thermal shock.

Get In Touch Today

Contact us to discuss your application, get samples

or schedule an estimate.