Dave's Hot Chicken

The Challenge

If you've ever had the privilege of trying Dave's Hot Chicken, you certainly know what all the hype is about. As one of the hottest new chain restaurants in the U.S., Dave's has been growing fast.

These projects came with challenges typical of the food service industry. Each space was located in existing buildings, many of which had previously housed other restaurants. This meant the floors were often worn, cracked, or damaged and required significant preparation to meet safety and performance standards.

The franchises also faced tight construction timelines. Flooring installation occurred in the final stages of the build process, leaving limited time to complete the work. Additionally, the project required two distinct systems: decorative, easy-to-clean flooring for the front of house and a more utilitarian system for the back of house, capable of handling grease, heavy cleaning, and thermal shock.

.jpg?width=600&height=700&length=700&upscale=true&name=Daves_Hot_Chicken_Hero%20(1).jpg)

.jpg)

The Solution:

Working through their contractor, Daves Hot Chicken connected with Resinwerks to develop a specialized flooring approach that would meet the unique needs of each space.

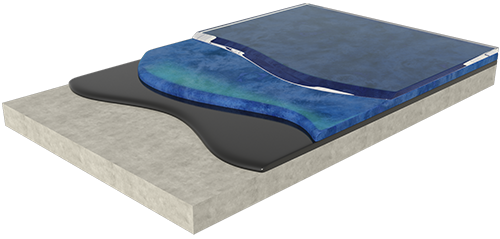

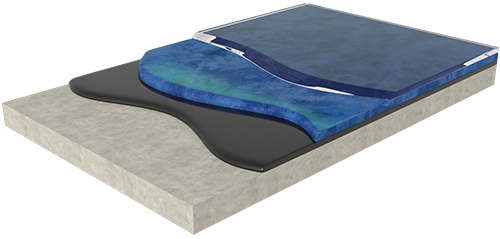

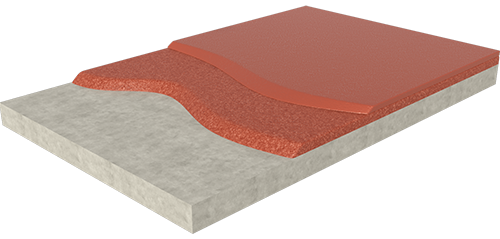

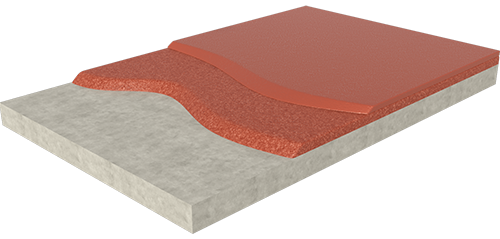

For the front of the house, a full metallic epoxy system featuring a primary smoke color with white and black accents, creating a visually striking surface that could withstand high foot traffic. The back of the house required a more industrial solution — a BioCem SLB polyurethane concrete system designed to resist thermal shock, grease, and chemical exposure and maintain a completely seamless, sanitary surface.

The installation process began with comprehensive surface preparation, including grinding the concrete to create an optimal profile and repairing any existing damage. A vapor barrier epoxy primer provided critical moisture protection, with subsequent layers including a metallic clear coat and a final HDC 100 urethane topcoat.

System Details

- System: Resinwerks Metallic Epoxy

- Base: Bio-Cure™ EP 1100

- Topcoat: LevelGuard™ EP

- System: Resinwerks Polyurethane Concrete

- Base: BioCem™ SLB Polyurethane Concrete

- Topcoat: HDC 100™ Urethane

The Results

The end result? Floors that are as reliable and hard-working as the franchises themselves.

The metallic system in the dining areas delivered a polished, modern aesthetic that enhanced the customer experience while standing up to heavy foot traffic and daily wear. In the back-of-house, the BioCem™ SLB system provided a seamless, durable, and slip-resistant surface capable of withstanding thermal shock, grease, and rigorous cleaning protocols.

Get In Touch Today

Contact us to discuss your application, get samples

or schedule an estimate.